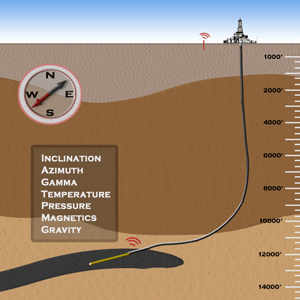

Electromagnetic Measurement While Drilling (EM MWD)

At Native Navigation, we're not easily satisfied with MWD systems and average performance is NOT acceptable to us. Which means we spare no expense at putting together top-notch MWD kits.

That's why you'll find ONLY the best performing MWD tools in the entire industry in our fleet. The Native Navigation line of EM tools is consistently tested up to 16,500 & 22,500 feet MD with a signal headroom to spare. Our systems offer unmatched speed, reliability, and operational depth. By down-linking, we can adjust virtually any parameter on the fly to adjust to conditions.

At the top of the system, a non-magnetic drill collar with an electrically insulated gap sub is used. To generate electromagnetic signals that propagate to the surface, a low-frequency FSK modulated signal is applied across the insulating gap. An upper electrode and the collar mounted dipole head are used to apply the signal across the gap. The gap sub-signal is generated by the power driver electronics unit.

Typically, two 29V, 29 Amp-hour batteries encased in pressure barrels are used to power the electric dipole system, although the use of three or more batteries is possible for situations where high power output for a long period is required. The borehole angular orientation and drill string tool face are measured by a directional sensor below the batteries. A gamma sensor is mounted directly below the directional sensor.

Features

- Proven design with high reliability, MTBF over 2500 hours

- Data transmission from depths of 14,000+ feet (4200+ meters) in favorable conditions

- Real-time Annular Pressure & Drill Collar Internal Pressure

- Rotation Sensing, Shock & Vibe, Memory Logging Capable

- Gamma Ray LWD

- Up to 16,500' TVD & 22,500 MD attained

- Enhanced decoding abilities

Applications

- Reduce or eliminate Survey time – Typically ½ day to 1 day time savings per well

- Underbalanced drilling

- High-speed drilling where fast data rates are required

- Low-pressure formations or lost circulation situations

- Virtually no LCM limitations/restrictions

For a quote on our systems please give us a call at (970) 424-5226 or click here to reach out to us online.